During the second half of the year 1944, work began on the construction of three large, semi-subterraneous bunkers in the Landsberg area. The purpose was to construct large, camouflaged, bomb-proof buildings in which the newest type of the jet-propelled Messerschmitt airplane "Me 262" could be build without interruptions by allied bombings. The three bunkers received the code names "Walnuß II" (walnut 2), "Weingut II" (vineyard 2), and "Diana II", and they were planned to be identical in construction.

According to rough estimates of the deputy chief of construction, Rudolf Neuhaus, the bunker "Weingut II" required the excavation of 35 million cubic feet of earth and the pouring of 11 million cubic feet of concrete.

According to rough estimates of the deputy chief of construction, Rudolf Neuhaus, the bunker "Weingut II" required the excavation of 35 million cubic feet of earth and the pouring of 11 million cubic feet of concrete.

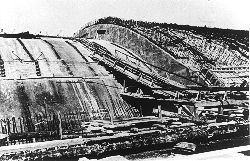

"Weingut II" was supposed to be a "thick-wall, arc-shaped building made out of steel-reinforced concrete" able to accommodate in its center a five-story building. The first plans called for 1,300 feet long concrete vault. Later the plans were altered and the concrete vault was shortened to 765 feet. The maximum width of the vault was 272 feet, and the height was 93 feet. The original plans called for a ceiling thickness of 16 feet. This was considered to be adequate to withstand 6-ton bombs. Shortage of materials resulted in a ceiling of only ten feet of concrete; however, this was augmented with an outside cover of gravel of another 16 feet.

The massive concrete vault was poured over a convex core of over 740,000 cubic feet of gravel. Underneath the gravel and along the length of the bunker, a tunnel was constructed out of steel reinforced concrete. Tracks were laid on the floor of this tunnel for a narrow-gauge train which was used to remove the earth and gravel core after the concrete vault was completed.

The massive concrete vault was poured over a convex core of over 740,000 cubic feet of gravel. Underneath the gravel and along the length of the bunker, a tunnel was constructed out of steel reinforced concrete. Tracks were laid on the floor of this tunnel for a narrow-gauge train which was used to remove the earth and gravel core after the concrete vault was completed.

The concrete arch itself consisted of 8 inches of light cement which included a grid work of supporting iron rods. On top of that, heavy concrete was pumped. Outer wooden scaffolding kept the concrete from sliding off the convex shape of the vault. Plans called for the construction of the concrete vault in nine sections. It took three to four days to complete one of the 85 foot sections.

The concrete arch itself consisted of 8 inches of light cement which included a grid work of supporting iron rods. On top of that, heavy concrete was pumped. Outer wooden scaffolding kept the concrete from sliding off the convex shape of the vault. Plans called for the construction of the concrete vault in nine sections. It took three to four days to complete one of the 85 foot sections.The gravel used as a support for the vault was removed through the tunnel that was dug underneath. This tunnel had hatches built into its ceiling through which the gravel could fall into the small-gauge railroad cars. To use a gravel mound to support a vaulted structure of this size and thickness was an innovation which was developed by Professor Dischinger of the Technical University of Berlin in order to save time and material for the war effort.

The actual construction of the "Walnuß II" bunker was carried out by the Karl Stöhr construction firm, that of "Weingut II" by the Leonhard Moll company, and that of "Diana II" by the firm Phillip Holzmann. The work inside the bunkers was contracted to the firms of Dyckerhoff & Widmann and Held & Francke.

The estimated cost for the work that the firm of Leonhard Moll did on the bunker "Weingut II" was estimated to be 20,179,700 Reichsmark. However, by the end of the war, the company completed only about 70,3% of this work for a total of 14,000,000 Mark.

According to a calculation made on July 6, 1944, by the firm Dyckerhoff & Widman for a national survey, a trained German construction worker earned 0.90 Reichsmark per hour, an untrained German worker between 0.60 and 0.80 marks, and a foreign "auxiliary" worker 0.60 marks. The official orders were that workers who were Jews should not be paid at all by their employers, nor should they receive any other compensation. In short, they should be treated as slaves.

For a Jewish concentration camp prisoner, the SS-administration calculated a daily expense of 0.60 Reichsmarks for clothing, food, and housing.

The Nazi government and the companies that worked for it saved many millions due to the slave labor of Jewish concentration camp prisoners. So far, all the firms that participated in the project have rigorously refused to pay compensations to former concentration camp prisoners.

A number of individuals who were associated with the planning and construction of the bomb-proof aircraft factory near Landsberg rose to positions of prominence in post-war Germany. Professor Hettlage was a financial expert from the highest echelons of the Nazi armament ministry and was involved with the overall planning, the cost estimates, and the financing of bomb-proof armament factories. Hettlage later became the second highest official in the ministry of finance of the Federal Republic of Germany. Dr. Guthsmuths was a leading figure in the Organization Todt which was in charge of the work force of project "Ringeltaube". He became second in command in the ministry of economics of the state of Bavaria. And Heinrich Lübke was the acting head of the engineering firm Schlempp which was in charge of all construction of bomb-proof airplane factories and made its plans based on slave labor from concentration camps. Lübke rose to occupy one of the two highest offices in the land, that of president of Germany

.In the 1950s, the only one of the three large bunkers that had come close to completion -- the one code-named "Weingut II" -- was taken over and completed by the German ministry of defense under Franz Josef Strauß. It is now the home of Luftwaffenwerft 31, a repair facility of the German Air Force.